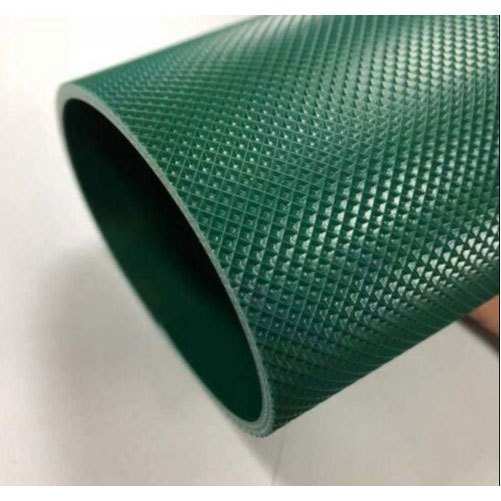

Effective material handling depends on high-Quality PVC Belting. The difference between PVC belting and rubber belting conveyors mainly lies in the quality of the material, which is important for different conveyor applications and industries.

Rubber belts are known for their durability and flexibility, making them ideal for heavy-duty and abrasive materials. They can handle a wide range of temperatures and are resistant to wear and tear, which is beneficial in demanding environments.

On the other hand, PVC belts are often more effective and suitable for lighter, less abrasive materials. Choosing the right type of belting ensures maximum performance, reduces maintenance costs, and extends the life of the conveyor system.

In addition to their robust functionality, rough top belting conveyors can be customized to meet specific operational needs. Options include varying belt widths, lengths, and materials to suit the demands of different applications. Advanced models may also integrate features like adjustable speeds, automated loading and unloading systems, and sensor technologies to optimize performance and enhance productivity.

Investing in a high-quality rough top belting conveyor can lead to significant improvements in workflow efficiency, safety, and overall operational effectiveness. These systems not only streamline material handling processes but also reduce the risk of damage to goods, thereby contributing to cost savings and improved output

Searching for high temperature resistant belting for your industrial applications? Look no further than Conveyor Supplies Africa’s range of PTFE Conveyor Belts.

Our PTFE Conveyor Belts are specifically engineered to withstand high temperatures, making them ideal for industrial applications where heat resistance and durability are essential. Whether you’re operating in the food processing, automotive, or manufacturing industry, our PTFE Belts provide reliable and durable material handling solutions that can withstand the toughest conditions.

These systems efficiently handle a wide range of items, from lightweight packages to heavy bulk materials, ensuring a smooth and continuous flow of goods.

The durable PVC material provides excellent resistance to wear and tear, making it ideal for high-volume operations. Additionally, the modular design of these conveyor belts allows for easy customization and maintenance, catering to the specific needs of different applications. Whether used in manufacturing plants, warehouses, or distribution centers, elevator PVC conveyor belts contribute significantly to enhancing productivity and operational efficiency.

The rhythmic hum of the conveyor was a testament to its reliability and precision, ensuring that each item reached its destination without delay. Workers moved with practiced ease alongside the conveyor, their movements synchronized with the steady flow of products. The smooth top belt, crafted from durable materials, glided seamlessly, reducing friction and wear. It was an essential part of the production process, embodying innovation and practicality in every inch.

These advanced conveyor belts are designed to efficiently transport large quantities of materials over long distances, offering unparalleled durability and reliability. Constructed with high-strength materials and sophisticated engineering, diamond belt conveyors can withstand the harshest of conditions, from extreme temperatures to abrasive environments.

Industries such as mining, construction, and manufacturing benefit greatly from the implementation of these systems. By reducing manual labor and increasing operational efficiency, they not only boost productivity but also enhance safety standards. The belts are often equipped with sensors and automated control systems that monitor performance in real-time, allowing for predictive maintenance and minimizing downtime.

PVC and PU cleated belting are known for their excellent resistance to chemicals and moisture, making them ideal for applications in the food processing, pharmaceutical, and manufacturing industries. They are also relatively inexpensive and easy to maintain, which makes them a cost-effective choice for many businesses.

On the other hand, PU cleated belts offer superior tensile strength and are highly resistant to abrasion, oil, and fat. This makes them particularly suitable for conveying heavy or sharp objects, as well as for use in harsh environments where durability is paramount. PU belts are often used in the packaging, automotive, and recycling industries.

Polyurethane belting provides excellent resistance to abrasion, chemicals, and temperature variations, making it an ideal choice for conveying materials in a variety of environments. These belts are commonly used in industries such as food processing, packaging, automotive, and manufacturing.

Their flexibility allows for smooth operation over pulleys and the ability to withstand high-tension loads without stretching or breaking. Additionally, polyurethane belts can be customized to meet specific requirements, including different thicknesses, textures, and colors.

Maintenance of polyurethane belting is relatively straightforward, requiring regular inspections to ensure optimal performance and longevity. By investing in high-quality polyurethane belting, businesses can enhance their operational efficiency, reduce downtime, and improve overall productivity.

The design of bare top conveyor belting ensures minimal slippage and maximum grip, making it ideal for moving heavy or bulky items. Additionally, its construction often includes materials that are resistant to wear and tear, ensuring longevity and reliability even under the most demanding conditions. Whether in a warehouse, factory, or processing plant, bare top conveyor belting plays a crucial role in streamlining operations and boosting productivity.

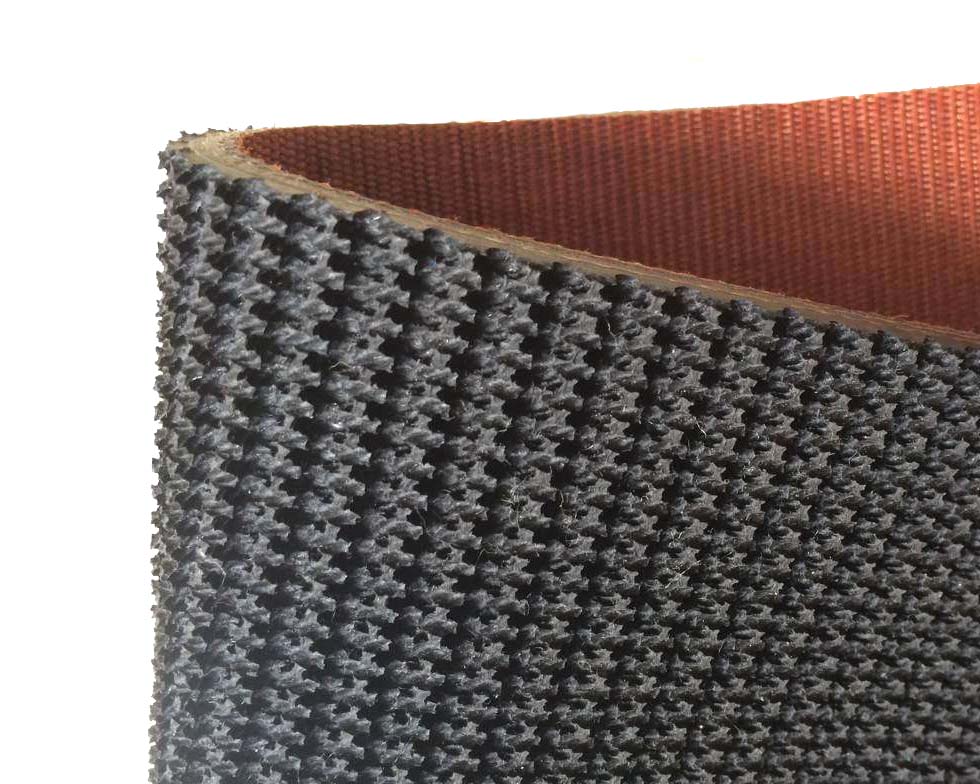

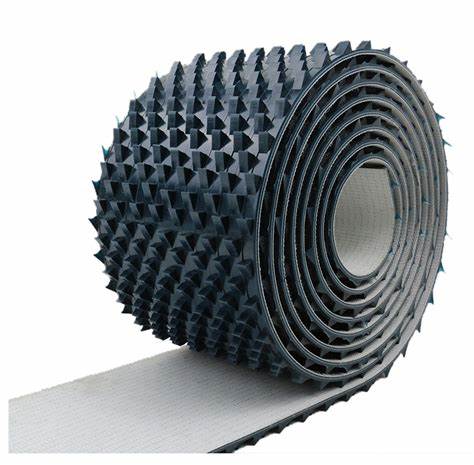

A saw tooth belt is a type of conveyor belt designed with a distinctive saw tooth pattern on its surface. This pattern provides enhanced grip and traction, making it ideal for handling materials that might slip or require extra stability during transport. Saw tooth belts are commonly used in industries such as manufacturing, packaging, and material handling, where precise movement and control are essential.

Corrugated PVC belting is a specialized conveyor belt designed with a corrugated or ribbed surface, providing increased grip and stability for transporting various materials. Made from durable PVC, these belts are resistant to wear, chemicals, and moisture, making them suitable for a wide range of industrial applications. The corrugated design helps to prevent slippage and ensures that materials, especially those with irregular shapes or slick surfaces, are securely transported even on inclines.

Corrugated PVC belting is commonly used in industries such as agriculture, food processing, packaging, and material handling. Its robust construction and enhanced traction capabilities make it an excellent choice for environments where reliable and efficient material movement is critical.

Finding quality PVC belting near you is crucial for ensuring the efficiency and longevity of your conveyor systems. Our quality PVC belting is engineered to deliver superior performance in demanding environments, offering strength, durability, and resistance to harsh conditions.

Whether you’re handling heavy loads, abrasive materials, or operating in extreme temperatures, our rubber belts are up to the challenge. Additionally, our belts provide excellent flexibility, minimizing downtime and maximizing productivity. By investing in our top-tier PVC belting, you can achieve smoother operations and increased reliability, ensuring your conveyor systems run at their best.

By choosing our quality PVC belting, you’re not just investing in a product but in the future of your operations. Our belts are designed to withstand the rigors of daily use, ensuring that your conveyor systems remain efficient and reliable over time. With superior resistance to wear and tear, they help reduce the frequency of replacements, thereby lowering your overall maintenance costs. Moreover, our belts are available in a variety of specifications to meet the unique needs of different industries, from food processing to manufacturing.

This versatility ensures that no matter your application, you can find a belting solution that perfectly fits your requirements. With our commitment to quality and customer satisfaction, we are your trusted partner in achieving operational excellence.

©2024. Conveyor Supplies Africa (Pty) Ltd | All Rights Reserved.

Africa's Trusted Conveyor Manufacturer!